The Application Principle Of Aluminum Powder Paste In Aerated Concrete

The Application Principle Of Aluminum Powder Paste In Aerated Concrete

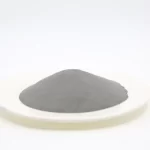

Product Description

Our aluminium pastes are used in the construction industry for producing autoclaved aerated concrete(AAC). As water based and paste type, it’s convenient to be added into the AAC block making machine, has few pollution on environment.

Product Characteristic:

Pastes with 65%, 70% of solid content are standard. Other solid contents and different Particle size are available to get the right hydrogen gas evaluation, pore structure, density compressive strength, reaction time (dwell time) fit in any production system.