Stripping powder coat from aluminum

Stripping powder coat from aluminum

Powder coating is a popular finishing technique used to protect and enhance the appearance of various metals, including aluminum. Over time, however, powder coatings can become faded, chipped, or damaged, diminishing the aesthetic appeal of the surface. Stripping powder coat from aluminum is a process that removes the existing coating, preparing the surface for a fresh application or other restoration methods.

The process of stripping powder coat from aluminum involves the use of specialized chemical strippers or abrasive methods. Let’s take a closer look at these methods:

1. Chemical Stripping

Chemical stripping is a common and effective method for removing powder coat from aluminum surfaces. It involves applying a chemical stripper specifically designed to break down the powder coating. The stripper is typically brushed or sprayed onto the surface and left to penetrate and soften the coating. Once the coating has loosened, it can be easily scraped or washed off, revealing the bare aluminum underneath.

Chemical stripping offers several advantages. It is relatively easy to use and does not require specialized equipment. It is also a gentle method that minimizes the risk of damaging the aluminum surface. However, it is crucial to follow the manufacturer’s instructions and safety precautions when using chemical strippers to ensure proper handling and disposal.

2. Abrasive Stripping

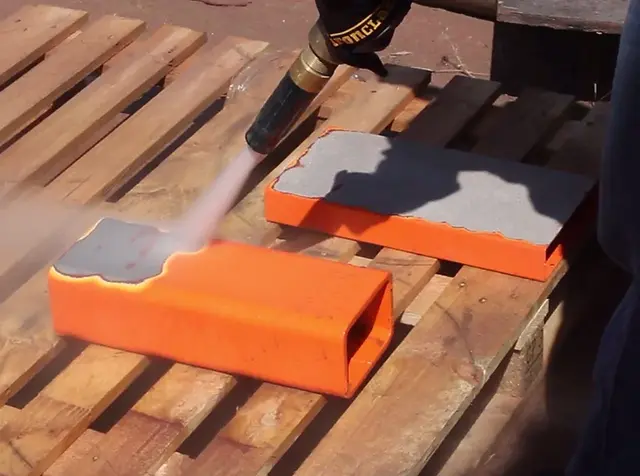

Abrasive stripping is another method commonly used to remove powder coat from aluminum surfaces. This method involves mechanically abrading the coating using abrasive materials such as sandpaper, wire brushes, or abrasive blasting. The abrasive action gradually wears away the powder coating, exposing the bare aluminum.

Abrasive stripping is effective for removing thick or stubborn powder coatings. It allows for precise control over the removal process and is suitable for smaller or intricate surfaces. However, it can be more time-consuming and labor-intensive compared to chemical stripping. It is also important to exercise caution and use appropriate safety measures, such as wearing protective eyewear and masks, when performing abrasive stripping.

The Benefits of Stripping Powder Coat from Aluminum

Stripping powder coat from aluminum offers several benefits, including:

1. Surface Restoration

By removing the old and damaged powder coating, stripping allows you to restore the original appearance of the aluminum surface. This can help improve the aesthetics of your products or structures, giving them a fresh and rejuvenated look.

2. Preparation for New Coatings

Stripping powder coat from aluminum is an essential step when you want to apply a new powder coating or other finishing techniques. By removing the existing coating, you create a clean and smooth surface that allows for better adhesion and longer-lasting results.

3. Cost and Time Efficiency

Stripping powder coat from aluminum can be a cost-effective alternative to replacing the entire surface. Instead of investing in new aluminum products or structures, you can restore the existing ones by removing the old coating. This saves both time and money while still achieving desired results.

Choosing the Right Stripping Method

When it comes to stripping powder coat from aluminum, it is essential to choose the right method based on the specific requirements of your project. Consider factors such as the thickness of the coating, the size and intricacy of the surface, and the desired level of precision. Chemical stripping is generally more suitable for larger surfaces and thinner coatings, while abrasive stripping offers better control for smaller or detailed areas.

It is also crucial to prioritize safety during the stripping process. Wear appropriate protective gear, work in well-ventilated areas, and follow the instructions provided by the manufacturer of the chosen stripping method.

In conclusion, stripping powder coat from aluminum is a viable solution for restoring the beauty and integrity of your surfaces. Whether using chemical stripping or abrasive methods, this process allows you to remove old, worn-out coatings and prepare the aluminum for new applications or other restoration techniques. By choosing the right stripping method and following safety guidelines, you can achieve impressive results and prolong the lifespan of your aluminum surfaces.