Aluminum is one of the most widely used metals in the world, known for its lightweight, corrosion resistance, and high thermal and electrical conductivity. It is commonly found in various industries, from aerospace to packaging. But when we talk about aluminum, is it possible to obtain it in a 100% pure form? This blog post will explore the concept of purity in aluminum, the methods of refining, and the practicality of 100% pure aluminum in today’s applications.

The Concept of Purity in Aluminum:

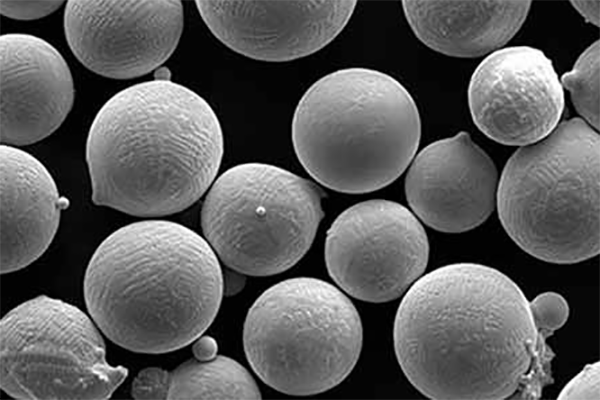

Aluminum in its purest form is a silvery-white metal that is soft and malleable. However, the term “100% pure aluminum” is somewhat of a misnomer in metallurgy. Aluminum as it is found in nature is always combined with other elements, and even when refined, it can contain trace amounts of impurities.

Refining Aluminum:

Bayer Process: The primary method of producing aluminum involves the Bayer Process, where bauxite ore is refined to produce alumina (aluminum oxide). This process removes many impurities but does not result in 100% pure aluminum.

Hall-Héroult Process: The subsequent step involves the Hall-Héroult Process, where alumina is dissolved in molten cryolite and reduced to metallic aluminum. Even with this electrolytic process, achieving 100% purity is not feasible due to the presence of trace impurities.

Practicality and Applications:

Alloys: In practical applications, aluminum is often alloyed with other metals such as copper, manganese, or silicon to enhance its strength and durability. These alloys are tailored for specific uses and provide superior performance compared to pure aluminum.

Commercial Purity: The term “commercially pure aluminum” refers to aluminum with a minimum of 99.00% aluminum content. This is the closest to “pure” aluminum that is commonly used in industry.

Impurities and Properties: The trace impurities in aluminum can actually influence its properties. For example, small amounts of iron and silicon can affect the metal’s strength and electrical conductivity.

Environmental and Economic Considerations:

Sustainability: The production of aluminum, even in its refined form, has environmental impacts, including energy consumption and the generation of waste products.

Recycling: Aluminum is highly recyclable, and recycled aluminum requires significantly less energy to produce than virgin aluminum. This makes recycling an important aspect of aluminum’s lifecycle.

Conclusion:

While it is technically impossible to achieve 100% pure aluminum due to the nature of metal refining and the presence of trace impurities, commercially pure aluminum (99.00% pure) is widely used across various industries. The slight impurities do not detract from its utility but can actually contribute to the metal’s desirable properties. As we continue to innovate and develop new technologies, the focus remains on producing aluminum that meets the specific needs of various applications while minimizing environmental impact.

Post time: 5 月-25-2024