Are you looking to build with AAC block (Autoclaved Aerated Concrete)? This article delves into the critical role of mortar in AAC block construction, focusing on selecting the best mortar to ensure structural integrity, durability, and performance. From understanding the unique properties of AAC block to the various mortar types available, this guide will provide you with the knowledge needed to make informed decisions for your construction project. Discover why choosing the best mortar is essential for a long-lasting and high-performing building.

1. What is AAC Block? Why Choose It?

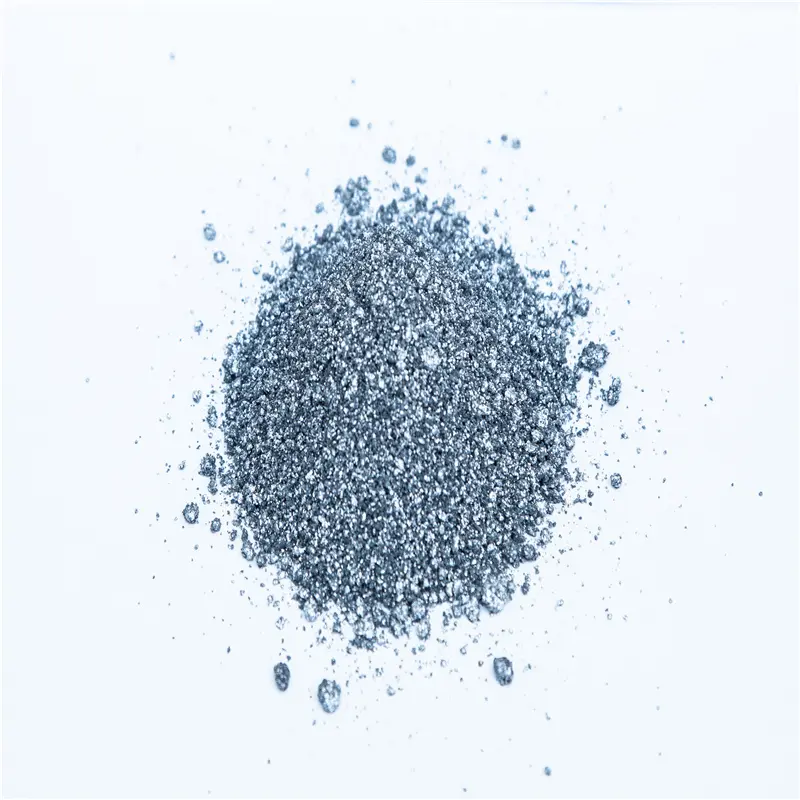

AAC block, or autoclaved aerated concrete, is a lightweight, precast building material known for its exceptional thermal insulation and fire resistance. Made from a mixture of sand, cement, water, and an expanding agent (typically aluminum powder), AAC block is cured under high pressure and temperature in an autoclave. The resulting product is a highly porous material that offers numerous advantages over traditional concrete block or brick.

Why choose AAC block? Because they’re lightweight blocks, easy to handle, and reduce construction time. Furthermore, their thermal insulation properties make them ideal for energy-efficient buildings. This makes AAC a key component in sustainable construction. These blocks have emerged as a popular choice for both residential and commercial building construction due to these properties.

2. Why Is Mortar Important for AAC Block Construction?

Mortar plays a vital role in AAC block construction, acting as the binding agent that holds the blocks together, ensuring the structural integrity of the masonry. The mortar fills the gaps between the blocks, distributing the load and preventing movement that could lead to shrinkage cracks or structural failure. Without a good mortar, the blocks wouldn’t stay together.

The mortar also contributes to the durability and water resistance of the wall. It’s essential for AAC block construction because, without the proper mortar, the wall won’t be strong and durable. In fact, using the best mortar helps maintain the thermal insulation and seismic resistance properties of the AAC block. Think of mortar as the glue that makes the building stand strong and last for a long time, contributing to the longevity of the building.

3. Types of Mortar: Cement, Masonry, and Thin-Bed Mortar

There are several types of mortar available for AAC block construction, each with unique characteristics.

-

Cement Mortar: This is a basic mortar made from a mix of cement, sand, and water. It is the most commonly used in the construction of walls. While it can be used for construction with AAC block, it might not always provide the best performance due to its higher density and potential for creating thermal bridges. If you’re considering using AAC, you might want to look into better options. Using AAC is all about choosing the right construction materials.

-

Masonry Cement: This type of mortar combines cement with other additives for improved workability and adhesion. These additives often include fly ash or gypsum which may help reduce shrinkage cracks. Masonry cement is generally a good option for AAC block, as it offers better bonding properties. This type of mortar is often a good choice, because it can be readily achieve the desired consistency.

-

Thin-Bed Mortar: This is a specially formulated mortar designed specifically for AAC block. It is usually a dry powder that’s mixed with water on-site to create a thin, uniform layer between the blocks. Thin-bed mortar offers several advantages, including faster construction time and reduced thermal bridging. It provides the best thermal performance. This is often called the best mortar, because it is often the best mortar for infrabloc AAC.

4. Key Properties of Mortar: Workability, Adhesion, and Cure

When choosing the right mortar for your AAC block project, there are several key properties to consider. Understanding these properties is essential for a successful outcome.

-

Workability: This refers to how easily the mortar can be mixed, spread, and applied. Workability is important for the on-site convenience of your construction project. Mortar with good workability allows for easy and uniform application, ensuring proper coverage and adhesion. The mortar should be easy to work with, making the construction process smooth.

-

Adhesion: Adhesion refers to the mortar’s ability to bond to the AAC block. A mortar with excellent adhesion ensures a strong and long-lasting bond, preventing water penetration and contributing to the overall durability. Proper adhesion ensures the structural integrity of the wall.

-

Cure: The cure is the process by which the mortar hardens and gains its strength. This is important because the mortar needs time to cure properly to reach its full strength. The cure of mortar is highly influenced by environmental conditions. The cure process affects the final compressive strength and durability of the mortar. During the cure process, it’s important to consider the weather conditions, which can influence the setting time of the mortar.

5. Cement Mortar vs. Specially Formulated Mortar: Which is Best?

The choice between standard cement mortar and specially formulated mortar depends on your specific project needs.

-

Cement mortar, while readily available and cost-effective, may not always be the best mortar for AAC blocks. It can sometimes lead to thermal bridging and shrinkage cracks if not mixed and applied correctly. Cement mortar can be used in the construction of AAC block walls. This type of mortar is also called grey cement.

-

Specially formulated mortar, such as thin-bed mortar, is designed specifically for AAC block. It typically offers better adhesion, lower thermal conductivity, and reduced risk of cracking. Though more expensive, it often provides superior performance and is generally considered the best mortar for AAC block jointing mortar because it is often the best mortar. This type of mortar provides a good balance between workability and compressive strength.

6. Factors to Consider When Choosing the Best Mortar

Several factors should influence your decision when selecting the right mortar for your AAC block construction.

-

AAC Block Type: Different AAC block products may have specific mortar requirements. Some manufacturers recommend using certain mortar types to achieve the best results. Be sure to know the exact block types.

-

Climate and Environmental Conditions: Weather conditions during application and cure play a role in the performance of the mortar. Ensure your mortar is suitable for the environmental conditions of the construction due site. Temperature and humidity affect the setting time and final strength of the mortar.

-

Building Code Compliance: Make sure the mortar complies with local building code requirements. This involves checking for certifications and ensuring that the materials meet all the necessary standards. AAC blocks are lightweight, and that means that you should check local building code to ensure compliance.

-

Cost: While thin bed mortar might be more expensive upfront, its benefits, like reduced construction time and improved performance, can lead to cost savings in the long run.

-

Project Size and Complexity: For large or complex projects, it’s often best to consult with experts to determine the best mortar mix.

7. Best Practices for Mixing and Applying Mortar for AAC Blocks

Proper mixing and application of the mortar are crucial for ensuring the performance of the AAC block wall. Following these best practices will help you achieve the best results.

-

Mixing: Always follow the manufacturer’s instructions for mixing the mortar. Use the correct water-to-mortar ratio to achieve the desired consistency. Avoid over-mixing, which can reduce the mortar’s strength. Make sure you use mix of cement with the other materials.

-

Application: Apply the mortar evenly to the blocks, ensuring complete coverage. With thin bed mortar, use a notched trowel to create a uniform layer. Too much or too little mortar can compromise the bond and the structural integrity.

-

Layer Thickness: With thin bed mortar, the layer should be as thin as possible, typically around 2-3 mm. This minimizes thermal bridging and allows for faster cure.

-

Jointing: Ensure proper alignment and level of the blocks, creating consistent joints. If there is too much mortar, you will have problems.

-

Cure: Protect the newly laid masonry from direct sunlight and excessive drying during the cure period. This is to help the mortar reach its full strength.

8. Addressing Common Challenges in AAC Block Construction

Despite the advantages of AAC block, certain challenges can arise during construction. Here’s how to address them:

-

Shrinkage Cracks: These cracks are typically caused by improper mortar selection, application, or cure. Using specially formulated mortar and following best practices will help prevent shrinkage cracks.

-

Thermal Bridging: This occurs when heat easily transfers through the mortar, reducing the thermal insulation properties of the wall. Using thin-bed mortar and avoiding thick mortar joints can minimize this.

-

Water Penetration: Ensure the mortar has good water resistance to prevent water penetration. Use mortar designed for exterior applications and take precautions during the construction process.

-

Improper Adhesion: If the mortar doesn’t bond well, it can lead to structural problems. Proper surface preparation, correct mortar selection, and following application guidelines are vital.

9. The Future of AAC Block and Mortar in Sustainable Construction

AAC block and its accompanying mortar play an increasingly important role in sustainable construction.

AAC block is a building material made with fly ash, which is a byproduct from power plants, helping to divert waste from landfills. The AAC blocks are lightweight, making them easy to handle and reducing transport emissions. Advancements in mortar technology are leading to even better performance, including improved thermal insulation, lower carbon footprint, and enhanced durability. These blocks have emerged as a core part of the industry due to their qualities. The construction industry due to reduce its environmental impact continues to drive innovation in these materials. AAC block is great for greener construction. The construction industry due to reduce its environmental impact continues to drive innovation in these materials. As a result, the use of AAC blocks is growing as we strive for more sustainable construction.

10. Conclusion: Ensuring a Successful AAC Block Construction Project

In conclusion, selecting the best mortar is a crucial part of any AAC block construction project. Whether you are building with AAC block to manufacture aerated concrete or for a construction project, the right mortar enhances structural integrity, durability, and performance. Understanding the different types of mortar, their properties, and the factors that influence their selection is paramount to achieving a long-lasting and energy-efficient building. By following the guidelines and best practices outlined in this article, you can make informed decisions and ensure the success of your AAC block construction. From this knowledge, you can start your block construction with confidence.

Key Takeaways:

- AAC block is a building material known for its lightweight, thermal insulation, and fire-resistant properties.

- Mortar is vital for bonding AAC blocks, ensuring structural integrity, and contributing to durability.

- Thin-bed mortar is often the best mortar for AAC block due to its superior performance.

- Key mortar properties include workability, adhesion, and cure.

- Follow best practices for mixing, application, and cure to achieve the best results.

Ready to start your project? Reach out to BTZmoc to learn more about our high-quality AAC block and mortar solutions, designed to meet the needs of your construction project! With 7 production lines, we specialize in these AAC products!

Contact Us to get started today!

Learn about our other AAC products: Aluminium pastes for aerated concrete, ALC Wallboard, and AAC Block.

Post time: 2 月-21-2025