This article provides a detailed overview of the best mortar options for use with Autoclaved Aerated Concrete (AAC) blocks, emphasizing the importance of choosing the right materials for optimal structural integrity and performance. It is worth reading because understanding the nuances of AAC block construction, specifically the mortar used, is critical for builders, contractors, and distributors aiming for durable, energy-efficient, and cost-effective construction projects. We’ll draw on our experience at BTZmoc, a leading Chinese factory, to give you the best information.

1. What is AAC Block and Why is Mortar Choice Crucial?

Autoclaved Aerated Concrete (AAC) block is a lightweight, precast building material made from a mixture of cement, lime, sand, water, and an expansion agent (typically aluminum powder). The aluminum powder reacts with the other ingredients, creating millions of tiny air pockets, giving AAC its characteristic porous structure. This makes AAC blocks significantly lighter than traditional concrete blocks or bricks, while still offering excellent strength and durability.

Choosing the right type of mortar is paramount in AAC block construction. The mortar acts as the binding agent, holding the blocks together and ensuring the structural integrity of the wall. Because AAC blocks have a unique cellular structure and are typically installed with very thin joints, standard cement mortar isn’t always the best choice. The ideal mortar needs to provide strong adhesion, accommodate the lightweight nature of AAC, and prevent issues like cracking or shrinkage.

2. What are the Key Ingredients in AAC Block Jointing Mortar?

AAC block jointing mortar, also known as thin-bed mortar, is a specially formulated adhesive designed for use with AAC blocks. While the specific ingredients are used and proportions can vary, the core components typically include:

- Cement: Provides the primary binding strength.

- Graded Sand: Fine sand particles contribute to the mortar’s workability and strength.

- Polymers: Enhance adhesion, flexibility, and water resistance.

- Additives: These can include water retention agents, which help the mortar cure properly and prevent it from drying out too quickly, especially in hot or dry environmental conditions.

- Water.

The exact formulation is crucial to ensure proper bonding with the AAC block’s surface. The ingredients slightly differ from traditional cement mortar, emphasizing adhesion and minimizing thickness.

3. Traditional Cement Mortar vs. Thin-Bed Mortar for AAC Blocks: Which is Better?

Cement mortar, traditionally used for brick masonry, is a mixture of cement and water, sand, and sometimes lime. While it’s strong and durable, it’s not ideal for AAC blocks for several reasons:

- Thickness: Traditional cement mortar is typically applied in thicker layers (10-12mm), which can add unnecessary weight and reduce the thermal insulation benefits of AAC.

- Adhesion: Cement mortar may not bond as effectively with the smooth surface of AAC blocks, potentially leading to weak joint formation.

- Water Absorption: AAC blocks are highly absorbent. Traditional mortar can lose water to the blocks too quickly, hindering proper curing and reducing strength.

Thin-bed mortar, on the other hand, is specifically designed for AAC blocks. It is applied in very thin layers (2-3 mm) and offers several advantages:

- Enhanced Adhesion: The polymer additives in thin-bed mortar create a strong bond with the AAC block surface.

- Reduced Thermal Bridging: The thin joints minimize heat transfer, improving the overall insulation performance of the AAC wall.

- Faster Construction: Thin-bed mortar sets quicker, speeding up the building process.

- Material Saving: The quantity of mortar for AAC blocks is many times less than the quantity for bricks.

Best mortar choice for AAC: Thin-bed mortar is undeniably the best AAC block jointing solution.

4. How Does Thin-Bed Mortar Improve AAC Block Construction?

Thin-bed mortar, also known as AAC block jointing mortar, offers multiple improvements to AAC block construction:

- Enhanced Structural Integrity: The strong adhesion of thin-bed mortar creates a monolithic structure, maximizing the load-bearing capacity of the AAC wall.

- Improved Thermal Performance: By minimizing the thickness of the joints, thin-bed mortar reduces thermal bridging, contributing to better energy efficiency. This is a key selling point for clients like Mark Thompson, who prioritize energy-efficient building solutions.

- Faster Construction: The quick setting time of thin-bed mortar allows for faster laying of AAC blocks, reducing labor costs and project timelines. This addresses one of Mark’s pain points: shipment delays impacting construction schedules.

- Reduced Material Consumption: Less mortar is needed, leading to cost savings and reduced environmental impact.

5. What are the Advantages of Using AAC Blocks and Thin-Bed Mortar?

The combination of AAC blocks and thin-bed mortar offers a compelling set of advantages:

- Lightweight: AAC blocks are significantly lighter than traditional bricks or concrete, reducing the dead load on the structure and making handling easier.

- Excellent Thermal Insulation: The air pockets within AAC blocks provide excellent insulation properties, reducing heating and cooling costs.

- Fire Resistance: AAC is non-combustible and offers excellent fire resistance.

- Sound Insulation: AAC blocks provide good acoustic insulation, reducing noise transmission.

- Workability: AAC blocks are easy to cut, shape, and drill, making them versatile for various construction needs.

- Durability: When properly installed with thin-bed mortar, AAC structures are strong and durable and long-lasting.

- Cost-Effectiveness: AAC is produced at a reasonable cost, and using AAC blocks provides savings in other areas of construction, from reduced labor time to smaller foundation requirements.

6. How to Properly Apply Thin-Bed Mortar for AAC Block Laying?

Laying of AAC blocks with thin-bed mortar requires careful attention to detail:

- Surface Preparation: Ensure the AAC block surface is clean, free of dust, and slightly dampened. Avoid soaking blocks as this can hinder adhesion.

- Mixing: Follow the manufacturer’s instructions for mixing the thin-bed mortar. Typically, it involves adding water to the ready-to-use mortar mix and mixing until a smooth, consistent putty-like consistency is achieved.

- Application: Use a notched proper trowel specifically designed for thin-bed mortar application. Apply a uniform layer of mortar, typically 2-3 mm thick, to the horizontal and vertical surfaces of the blocks.

- Block Placement: Carefully lay the blocks onto the mortar bed, ensuring proper alignment and level. Lightly tap the blocks with a rubber mallet to achieve superior leveling and ensure full contact with the mortar.

- Jointing: Remove any excess mortar that squeezes out from the joints.

- Cure the Joints: Protect the joints from excessive moisture loss during the initial curing.

7. What are the Common Mistakes to Avoid When Working with AAC Blocks and Mortar?

- Using the Wrong Mortar: Using traditional cement mortar instead of thin-bed mortar is a major mistake that can compromise the structural integrity and thermal performance of the wall.

- Incorrect Mortar Consistency: Too much or too little water in the mortar mix can affect its adhesion and strength.

- Uneven Application: Applying the mortar unevenly can lead to weak spots and uneven walls.

- Improper Block Alignment: Poorly aligned blocks can create structural weaknesses and aesthetic issues.

- Ignoring Weather Conditions: Extreme weather conditions (hot, dry, or freezing) can affect the curing process of the mortar. Take necessary precautions, such as shading the work area or using admixtures.

- Failing to make necessary adjustments: The surface of earth is never uniform, but AAC blocks with thin joints allow for easier adjustments than traditional masonry.

8. How Does AAC Block Construction Compare to Traditional Brick Masonry?

| Feature | AAC Block Construction | Traditional Brick Masonry |

|---|---|---|

| Weight | Lightweight | Heavier |

| Thermal Insulation | Excellent | Moderate |

| Fire Resistance | Excellent | Good |

| Sound Insulation | Good | Moderate |

| Construction Speed | Faster | Slower |

| Mortar Thickness | 2-3 mm (Thin-bed) | 10-12 mm (Cement Mortar) |

| Cost | Generally more cost-effective | Can be more expensive |

| Masonry strength | Compressive strength is usually lower, but overall structural integrity with proper mortar can match. | High compressive strength. |

AAC block construction offers several advantages over traditional bricks or concrete applications, particularly in terms of weight, insulation, and construction speed. It is becoming increasingly popular in modern construction, especially for residential and industrial buildings. Blocks are increasingly used in both load-bearing and non-load-bearing walls, for interior and exterior applications.

9. What are the Environmental Benefits of Using AAC Blocks?

AAC blocks are considered an environmentally friendly building material for several reasons:

- Resource Efficiency: AAC production typically uses less raw material than traditional concrete blocks.

- Energy Efficiency: The excellent insulation properties of AAC reduce energy consumption for heating and cooling buildings.

- Reduced Waste: AAC blocks can be easily cut and shaped, minimizing waste on construction sites.

- Recyclability: AAC can be recycled, although this is not yet widespread practice.

- Use of Industrial by Products: Some AAC manufacturers use fly ash, a byproduct of coal-fired power plants, as a partial replacement for cement, further reducing the environmental footprint.

10. Where Can I Find High-Quality Aluminum Paste and AAC Products?

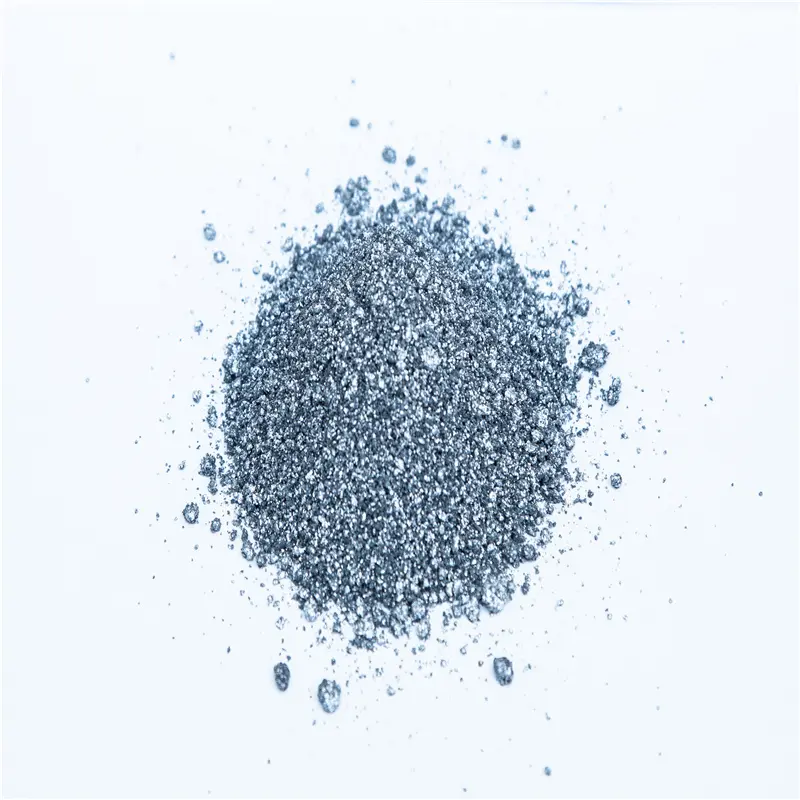

At BTZmoc, we are a leading Chinese factory with seven production lines dedicated to producing high-quality building materials for the aerated concrete industry. Our main products include:

- Aluminium pastes for aerated concrete: Our aluminum pastes are formulated for optimal gas generation in AAC production, ensuring consistent performance and reliable results. We offer various formulations to meet different AAC density requirements. This directly addresses Mark Thompson’s key concern about quality consistency.

- ALC Wallboard: Our ALC wallboards are lightweight yet strong, offering excellent thermal and acoustic insulation. They comply with relevant building standards, providing peace of mind for clients like Mark, who prioritize code compliance.

- AAC Block: Our AAC blocks are dimensionally accurate, ensuring easy installation and a high-quality finish.

One of our product pages give more details.

We export to major markets including the USA, North America, Europe, and Australia. We understand the needs of customers like Mark Thompson, who value quality, consistency, competitive pricing, and reliable logistics. Our team, led by Allen, is committed to providing excellent customer service and technical support. We regularly attend industry exhibitions, offering another avenue for potential customers to connect with us.

Key Takeaways

- AAC blocks are a lightweight, energy-efficient, and versatile building material.

- Thin-bed mortar is the essential adhesive for AAC block construction, providing superior adhesion, thermal performance, and construction speed compared to traditional cement mortar.

- Proper application techniques and attention to detail are crucial for successful AAC block construction.

- AAC block construction offers significant advantages over traditional brick masonry, including weight reduction, improved insulation, and faster construction.

- AAC blocks are an environmentally friendly building material.

- BTZmoc is a reliable supplier of high-quality aluminum paste and AAC products, catering to the needs of international clients.

- When choosing the right type for your building projects, always ensure that it matches the specific construction requirements.

- Among various construction materials, light weight blocks like AAC stand out. Unlike other bricks or concrete, AAC’s unique properties offer exceptional mortar stands and thin bed options, making it a top choice for enhancing masonry strength.

By understanding the properties of AAC blocks and the importance of choosing the right mortar, builders and contractors can create durable, energy-efficient, and cost-effective structures. This is why the message of this article is so important, and we hope it’s helped you better understand the nuances of building with AAC.

Post time: 3 月-08-2025