China aluminium powder 320 mesh factory

China aluminium powder 320 mesh factory

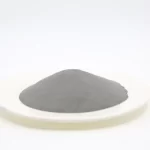

Aluminium powder 320 mesh is a fine-grade powder manufactured from high-quality aluminium. The “320 mesh” designation refers to the particle size, indicating that the powder passes through a 320-mesh sieve, resulting in particles that are approximately 44 microns in size. This fine particle size makes aluminium powder 320 mesh an ideal choice for applications that require a smooth and homogeneous finish, excellent reactivity, and optimal performance.

Benefits of Aluminium Powder 320 Mesh:

High Purity and Consistency: Aluminium powder 320 mesh is known for its high purity level and consistent quality. Manufactured using advanced processes, it undergoes stringent quality control measures to ensure that it meets the highest industry standards. The uniform particle size distribution guarantees consistent performance, allowing for predictable and reliable results in various applications.

Superior Reactivity: The fine particle size of aluminium powder 320 mesh enhances its reactivity, making it an excellent choice for applications that require rapid chemical reactions. The increased surface area allows for better interaction with other substances, facilitating efficient combustion, and ensuring optimal results in processes such as pyrotechnics, explosives, and metal fuel formulations.

Versatile Applications: Aluminium powder 320 mesh finds a multitude of applications across diverse industries. It is commonly used in the manufacturing of paints, coatings, pigments, and dyes, where it acts as a pigment extender, providing enhanced color intensity and improved adhesion. Additionally, aluminium powder 320 mesh is utilized in the production of conductive inks, solar panels, thermite welding, metal foam production, and the creation of lightweight concrete and composite materials.

Lightweight and Durable: Aluminium powder 320 mesh offers the advantage of being lightweight while maintaining excellent strength and durability. This makes it a preferred choice in applications that require materials with high strength-to-weight ratios, such as aerospace components, automotive parts, and lightweight structural elements. Its ability to contribute to lighter and more fuel-efficient products has made it a valuable asset in various industries.

Applications of Aluminium Powder 320 Mesh:

Aluminium powder 320 mesh finds extensive use in a wide range of industries, including:

Automotive and Aerospace: Aluminium powder 320 mesh is utilized in the automotive and aerospace sectors for its lightweight properties. It is incorporated into components such as engine parts, body panels, and structural elements, contributing to weight reduction and improved fuel efficiency.

Coatings and Pigments: The fine particle size of aluminium powder 320 mesh makes it an ideal choice for the production of coatings, paints, and pigments. It imparts metallic sheen, reflectivity, and corrosion resistance, enhancing the appearance and durability of various surfaces, including automotive finishes, architectural coatings, and decorative applications.

Pyrotechnics and Explosives: Aluminium powder 320 mesh plays a crucial role in pyrotechnic displays, fireworks, and explosive formulations. Its reactivity and ability to rapidly release energy make it a key ingredient in creating dazzling visual effects and ensuring the safe and controlled ignition of explosive devices.

Construction and Composite Materials: Aluminium powder 320 mesh is employed in the construction industry for the production of lightweight concrete and composite materials. Its addition enhances the strength, thermal conductivity, and fire resistance of these materials, offering sustainable, energy-efficient, and durable solutions for modern construction projects.