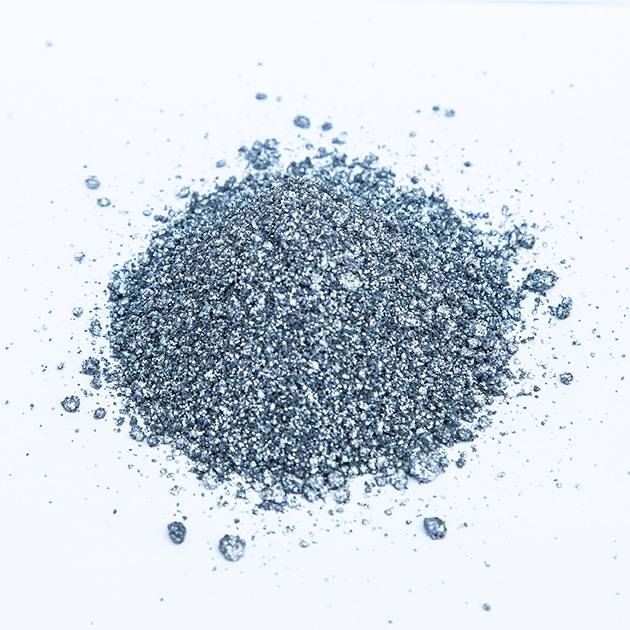

Characteristics Of Aluminum Powder Paste

Characteristics Of Aluminum Powder Paste

The function of aerated material in aerated concrete is to carry out a chemical reaction in the slurry, release gas and form small and uniform bubbles, so that the aerated concrete has a porous structure.

There are many types of gas generating agents, which can be divided into two categories: metal and non-metal. Metal gas generating agents include powders or pastes such as aluminum (AI), zinc (Zn), magnesium (M2), aluminum-zinc alloys and ferrosilicon alloys. Non-metals include hydrogen peroxide, rust carbide and sodium carbonate plus hydrochloric acid. However, since the gas generating reaction of metallic aluminum is relatively easy to control, the gas generating volume is large, and it is relatively economical, so at present, all countries in the world use aluminum powder or aluminum paste as the gas generating agent.

(1) Not easy to get dust

As we all know, aluminum is a kind of light metal. Its density is 2.7g/cm3. The aluminum is made into a very fine powder. Its particles vibrate or blow by a slight airflow, and it is very easy to fly around and disperse in the air for a long time. When the dust density of aluminum powder reaches 40-30mg per cubic meter of air, it will explode if it encounters sparks. The aluminum powder particles in the aluminum powder paste will form agglomerates or ointment under the protection and bonding. Under normal circumstances, there is no or very little possibility of flying. Safe and convenient when handling and weighing

(2) No static electricity

If the dry powder is transported pneumatically or quickly rubbed with other metals, it is easy to generate static charges. If the electrostatic field voltage reaches a certain level, it may form an electric spark and ignite the aluminum powder and cause a combustion explosion accident. Aluminum powder is not prone to this phenomenon.

(3) Not afraid of tide

Dry aluminum powder has the disadvantage of being afraid of tide and water during storage and transportation. When a small amount of water is mixed into aluminum powder, due to the combined effect of water and various traces of harmful solutes in the water, the aluminum powder may develop from slow oxidation to spontaneous combustion, or even cause a fire. Aluminum powder paste usually contains water-based protective agent, or it is a water-based product, so it is not afraid of moisture. However, external moisture can affect the solid content of the aluminum powder paste and should be avoided.

(4) Convenient for manual weighing

Because aluminum powder is easy to dust, it is extremely inconvenient for weighing operation. Manual weighing is very difficult, and mechanical weighing must have a well-sealed dust-proof or dust-removing device. Otherwise, the production will be affected. Aluminum powder paste basically has no such problem. However, if the aluminum powder paste is measured mechanically, it is best to prepare a suspension with a certain concentration, and measure it by volume.

(5) Has a certain foam stabilization function

Some aluminum powders need to add a variety of surface active substances during the manufacturing process. Some of these substances can play a role in stabilizing foam. Therefore, when the process conditions permit, the foam stabilizer can be omitted or used less.

(6) Production safety

The most prominent feature of aluminum powder paste is the safety of the production process. When grinding aluminum powder, a certain amount of dry powder and liquid grinding media are usually added to the mill at one time, and the whole process of grinding with a non-metallic grinding body is in an isolated and closed state, and there is no oxidation and combustion problem. Therefore, the safety of the production process is much higher than the production of aluminum powder.