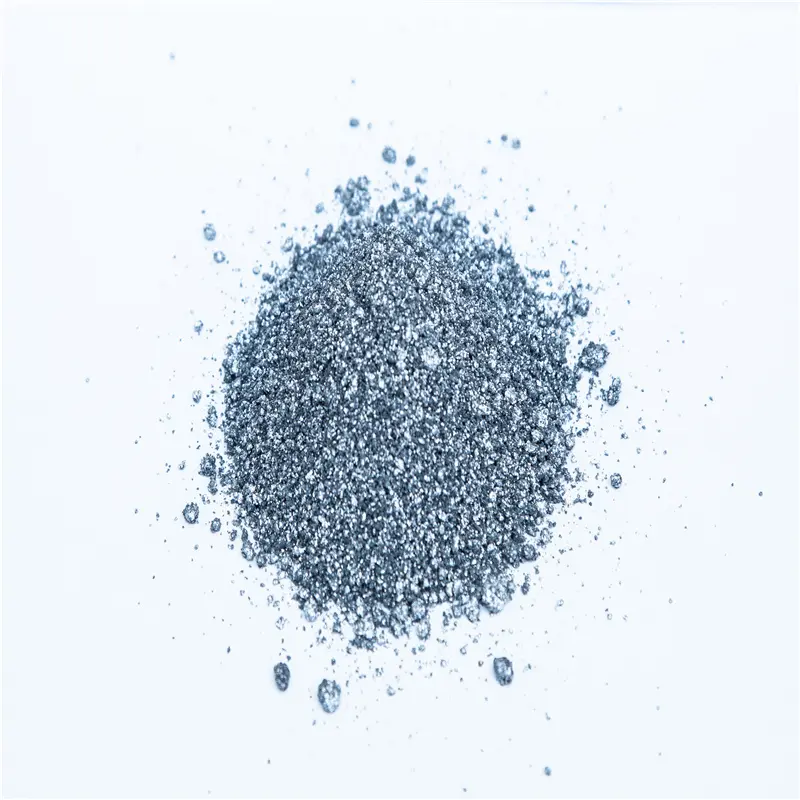

Aluminium pastes for aerated concrete

Aluminium pastes for aerated concrete

The main use of aerated aluminum powder for aerated concrete is to release gas from the chemical reaction between aluminum powder and silica and quicklime during the production process, so that the inside of the produced concrete block forms a porous structure. In the process of batching in the production process of aerated concrete blocks, the aerated is added to the aluminum slurry mixing tank, and after full stirring, it is put into the aluminum slurry measuring scale, and finally put into the pouring mixer together with raw materials such as quicklime, gypsum, fly ash, etc., the aluminum powder in the aluminum powder paste can react with alkaline substances in the aerated concrete slurry to release hydrogen, produce bubbles, and make the aerated concrete slurry expand to form a porous structure. So that the general weight of the aerated concrete block produced is 500-700kg/m3, which is only equivalent to 1/4-1/5 of clay bricks, 1/5 of ordinary concrete, which is one of the lighter concrete. The self-weight of ordinary brick and concrete buildings is reduced by more than 40%.